With around four million cricket bats being manufactured every year, the ongoing World Cup has spiked the market appetite for the Kashmir Willow. Syed Shadab Ali Gillani met the stakeholders to understand the challenges for the vibrant sector, especially the alleged raw material shortage

In not so distant past, when hockey was highly popular in the Indian Subcontinent, Kashmir had a thriving industry that made hockey sticks. Skilled artisans crafted hockey sticks by hand and it had an international market. Then, the main raw material that was being used was the Mulberry wood.

Post-partition, political geography changed so did manufacturing. Without giving up hockey-stick making completely, most Kashmir sports manufacturers got into cricket bat making.

One of the old companies that went through this change is Dar Sports, which has been around for nearly a century. Deeply rooted in sporting goods, it is one of Kashmir’s oldest bat-makers.

Owais Ahmed Dar, who now leads Dar Sports, is aware of the ‘strategic shift’ in the family business that took place soon after the partition. “We connected with Jalandhar, a major sports hub then alongside Sialkot in Pakistan,” Owais said. Sialkot, not far away from Jammu, was home to a number of Kashmiri artisans and continues to be a thriving sports manufacturing hub, a town that privately owns an airport and an air carrier with five aircraft. Post-partition, Jalandhar and Meerut became the twin sports manufacturing hubs on this side of the Redcliff divide.

After partition, the Dar family linked with Jalandhar, accessing the finest materials and expertise. This strategic move staged a cricket bat legacy spanning generations. Kashmir did not take much time to understand the reality that it is one-up already because it has the raw material – the willow.

Essential Raw Material

Native to Kashmir, the Kashmiri Willow is a deciduous tree that can grow up to 30 meters (98 feet). It has slender trunks and a narrow, conical canopy. In the autumn, its long, lance-shaped leaves turn bright yellow before dropping. These trees do well in the region’s moist and temperate climate, especially along riverbanks and in places with sufficient soil moisture.

For centuries, the fertile Kashmir lands have been a perfect home for willow. Its wood has been a versatile resource, used for making furniture, some parts of kitchenware, even wooden chappals (Khraw) used during winters, Tschalan (used for managing the fire-pot embers) and pheouh, the snow shovel besides fuel-wood and cattle feed. However, when the British introduced the cricket in subcontinent, the market triggered an appetite for bats. Post-1846, Kashmir used to be crowded with British soldiers merry-making in Kashmir during summers and this led to the gradual introduction of the game.

“When the British first arrived, they brought one cricket bat with them and asked a local carpenter, Allah Bakhsh from Sialkot, to fix it,” Fawzul Kabir, promoter of GR8 Sports in Sangam, said while offering an idea about the introduction of cricket bat manufacturing. “Allah Bakhsh replicated the bat’s style and returned it. The British told him that the wood used wasn’t suitable for making cricket bats; it needed a specific grain pattern. Allah Bakhsh learned this technique from them.”

Afterwards, the British decided to have their cricket bats made by Allah Bakhsh. “They asked where the wood came from, and the carpenter mentioned that it was willow from Kashmir. At that time, Kashmir was a princely state, and the Maharaja was committed to afforestation, including growing willow trees to meet various needs like fuel and fodder,” Fawzul added.

Upon discovering the presence of Kashmir willow trees, Allah Bakhsh set up a unit near Sangam (Anantnag). Willow wood was then transported to Sialkot via the Jhelum River, where cricket bats were crafted. After the partition, several sports equipment manufacturing factories relocated to India, marking the beginning of cricket bat production. The bat-making is now spread to a long stretch including Halmulla, Bejbehara and Sangam. Most of the vital infrastructure is located within the small industrial estate at Bejbehara, not accessible to others operating outside of it. It is now spread to a stretch including Halmulla and Bejbehara.

Mehmood Shah pointed out that natural seasoning is practiced in Kashmir. “We used to have a seasoning plant here, but it was damaged in the flood and needs to be upgraded,” he said. “With mechanised seasoning, our working cycle would be shorter, and as technology improves, our bat will be more competitive.”

Wedded To Willow

Kashmir, like China, Europe, Russia and other places has been growing willow for antiquity. However, the Veer, Vir, Veir that is now being cultivated owes its introduction to Britons almost a century ago. Writing in the fall of the nineteenth century, Walter Lawrence in his Valley of Kashmir noted the local willow was used as fuel and cattle feed.

Botany historians give credit to Kashmir’s first head of the forest department Mac Donnell, JC and his associate Redcliff, EAT, who took up the willow plantation work in 1916 around Wular Lake wetland, now called Ningli plantation. The objective was to offer a sustainable alternative to urban Kashmir’s fuel wood requirements and reduce the impact on forests. Subsequently, willow plantations came up around the wetlands of Haran-Shalbugh, Hokur-Sar, Mir Gund, Mamandanji, and Kitrenteng. These wetlands grew the indigenous willow verities.

Salix Alba (white willow) species was imported from England and France by Abbey in 1927 and planted in the Harran range. More cuttings were later introduced by Steane and Sir Peter H Clutterbuck. Locally, these willow species were popular with the names of the British officers who introduced them.

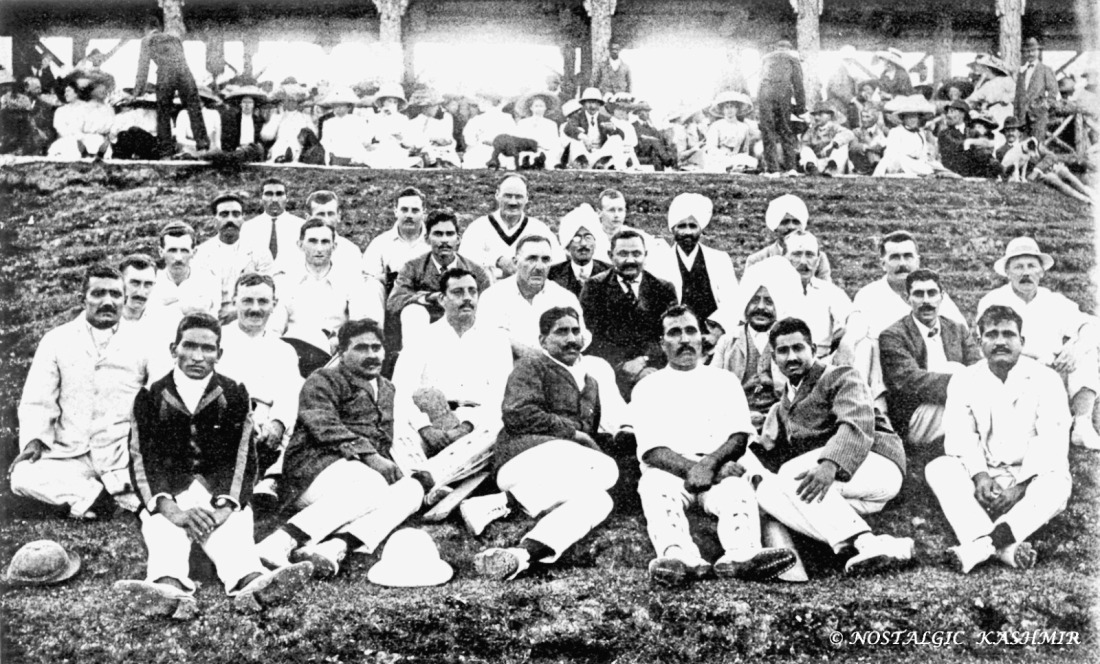

By 1922, Kashmir had its own cricket team, rather two teams. One team belonged to the British Resident in Srinagar and another team was sponsored by Maharaja Partap Singh (1848-1925). As part of his soft diplomacy, he was personally “playing” in Polo Grounds Srinagar in order to convey to the British that he was modern and forward-looking. This triggered a perpetual demand for the bats in local market.

Tradition to Innovation

Dar Sports emerged as the first cricket bat manufacturer in Kashmir to address the growing demand. “Cricket was initially introduced to Kashmir by the folks of Bijbihara. The rest of Kashmir mainly focused on football, while Bijbihara took the lead in cricket,” Fawzul said.

In 1974, Fawzul’s father initiated another unit in the region. “My father, who had studied in Bijbihara, noticed the growing interest in obtaining cricket bats from Sangam. He decided to establish a unit that became Gr8 Sports.”

Insisting that Gr8 Sports pioneered the full-scale production of cricket bats in Kashmir, Fawzul said the Indian cricket team’s victory in the 1983 World Cup triggered a surge in demand, rapidly expanding the industry. “In just one year, the number of bat manufacturing units skyrocketed from three to over eighty.”

Given the almost similar climate, both England and Kashmir grow willow but English willow bats are generally favoured over Kashmiri manufacture. Gr8 Sports was the first Kashmiri manufacturer to venture into the international market. He collaborated with industry players and deepened his understanding of bat manufacturing. “I introduced my products in international markets, and although they received appreciation, there were only a few takers,” Fawzul said. “I realised that my lack of name recognition posed a barrier.”

Main Hub

Since the early 1920s, Sangam has been a significant producer of Kashmir willow bats. However, these bats did not make their way to the international market until 2021 when the UAE adopted Gr8 bats for the T20 World Cup. Even Oman followed suit in using Kashmir willow bats.

The tradition of crafting bats in Sangam has been passed down through generations, with many sports equipment manufacturing units preserving this age-old art. After much hard work, Fawzul’s product gained acceptance in test cricket including the T20 World Cup. Later some players in the ongoing ODI World Cup from Afghanistan, Sri Lanka and Bangladesh chose Kashmiri willow bats. Gr8 Sports is the sole ICC-approved unit from Kashmir.

Scholarly Findings

In the 2014 Forest Products Journal paper Cricket Bat Industry as an Economically Viable Livelihood Option in Kashmir: Present Status and Future Prospects, Masoodi et al. found that despite underutilisation of production capacity, cricket bat manufacturing was a lucrative industry in Kashmir, providing reasonable profits and employment opportunities. The analysis of small, medium, and large-scale units showed decreases in production costs and increases in revenues and benefit-cost ratios with larger-scale operations. The industry was estimated to have significant future growth potential through export promotion, demand creation, and adoption of improved practices. Key constraints were a lack of quality raw materials and skilled labour, necessitating expanded cultivation of suitable willow, breeding programmes, training, and government investment incentives.

In the 2017 paper Willow Industries in Kashmir Valley: Present Dynamics and Future Prospects, Bhat et al. found that willow-based industries like cricket bat manufacturing, packing cases, and basketry provided employment and income generation opportunities in Kashmir. However, these industries faced raw material constraints due to the overexploitation of quality willow. The authors recommended expanded cultivation of suitable willow species, incentives for growers, improved practices, and government investment and branding support to realize the full potential of willow industries. Kashmir willow was found comparable to English willow for cricket bats. With appropriate development measures, willow industries could significantly benefit the Kashmir economy and livelihoods.

Global Reach and Recognition

Owais echoes concerns about shortages and waning interest among youth, calling for a training institute in Kashmir. He emphasises implementing comprehensive cultivation like in England to address the crisis caused by illegal trading.

With over twenty years of experience, veteran Majeed Ahmed stresses the global reputation of Kashmiri willow. “A single bat takes nearly a week to craft. But an international-grade one needs about ten meticulous days to meet weight and pressing standards,” Majeed said. “This craft came naturally over time. Unfortunately, Kashmiris tend to prioritise leisure over work, limiting involvement. But the potential is there, and with more opportunities, they could produce outstanding bats. Currently, we employ about four to five Kashmiris along with skilled workers from outside.”

Having dedicated decades to bat-making, Majeed has witnessed the industry’s evolution first-hand. His insights offer experience and hope for the future.

Challenges and Solutions

Popular cricketers, including Sachin Tendulkar, Yuvraj Singh, MS Dhoni, and Steve Waugh, among others, have wielded Kashmiri willow bats from Sangam, further cementing the brand’s reputation for excellence in the cricketing realm. While it is a documented reality, the crisis remained because of an absence of branding.

Made in Kashmir from the Kashmir willow, these bats passed as creations of companies that actually do not manufacture at all. They purchase bats from Kashmir and brand them with their own stickers ensuring Kashmir goes missing in the entire story. Manufacturers proudly affirm that cricketing legends like Sachin Tendulkar have employed Kashmir willow bats – he achieved his 35th international century in 2012 using one of Kashmir bats.

Among the key players in the global cricketing industry are major Indian companies like SS, SG, GM, Gray-Nicolls, DSC, Kookaburra, BDM, BAS, and Spartan Sports. Production hubs are scattered across Jammu-Kashmir, Uttar Pradesh, Rajasthan, Punjab, Haryana, and Gujarat.

Fawzul underlines the burgeoning exports to England, attributed to competitive pricing. “Manufacturers point to substantial recent growth. In 2021, 35,000 bats were exported from Kashmir, which soared to 135,000 in 2022. As of this year, exports have already surpassed 250,000, with more time still left,” Fawzul said.

Yawar Ahmed Dar of Frontline Sports tends to favour tennis bat production over leather ones. Tennis bats are basically cricket bats that are lighter, do not require hard-pressing and are used in playing a hard tennis ball. Most of these bats are unlabelled, leaving that choice to the buyers.

Dar also underscores a significant 50 per cent shortage in raw materials, often requiring them to be sourced from nearby regions. “Regrettably, there is a substantial annual wastage of withies. These young wands are frequently harvested for fodder and, once stripped of their leaves, are often burned as a source of fuel,” Dar said.

In the good old days, much of the equipment was crafted from Shahtoot tree wood. Later, willow wood took centre stage due to its exceptional quality, garnering international recognition. However, with the waning interest in hockey over the years, the demand for hockey sticks dwindled, leading to a resurgence in the bat industry.

In recent times, the future of the Kashmiri willow industry has become a matter of concern for many stakeholders. A shortage of raw materials, primarily stemming from a declining supply of willow trees, now poses a threat to the livelihoods of artisans and the rich heritage of this craft.

Dr NA Pala, an Assistant Professor in the Division of Silviculture and Agroforestry at the Faculty of Forestry, Sher I Kashmir University of Agriculture Science and Technology (SKUAST) Kashmir, has been monitoring the raw material scarcity, particularly concerning cricket bat willows in Kashmir. “Given the high demand for cricket bats made from Kashmiri willow, it is imperative to raise awareness among stakeholders and the farming community about cultivating this unique female cultivar on land that may not be suitable for agriculture or horticulture,” Pala said.

Underscoring the potential for these trees to be cultivated in various agro-forestry settings, such as boundary plantations, bunds, and woodlots, Pala regretted: “It takes approximately 10-12 years for these trees to mature for industrial use.” He emphasised the crucial role of these trees in sustainable development, citing their contribution to environmental conservation, carbon sequestration, and climate change mitigation due to their rapid growth. He also mentioned the ongoing efforts by the Faculty of Forestry to collect and distribute this vital cultivar to concerned stakeholders.

Some people suggest that policymakers should explore the possibility of planting willow on the banks of the Jhelum banks and the Flood Spill Channel. This, they believe, will make the embankments strong and improve the air quality.

Dr Parvez Sofi, Professor and Head of SKUAST-K’s Division of Forest Products and Utilisation, echoed concerns about the raw material shortage. “The willows used for making cricket bats are primarily of the Salix Alba variety Caerulea, a female cultivar,” noted Dr Sofi. “Almost 95 per cent of the willow population in Kashmir consists of Salix Alba males, making it challenging to source the appropriate raw material for bat manufacturing.” He emphasised the urgency of addressing this deficit. “We need to debunk the myth that Kashmiri willow is inferior to English willow, as they are similar.”

A Flourishing Industry

Fawzul is also concerned over the potential depletion of willow resources and possible industry extinction. He stresses the necessity of a sustainable plantation initiative and highlights the impact of pencil and plywood manufacturing on raw material shortages.

“Willow cultivation has seen a steady decline in recent years. Despite its growing importance, farmers seem reluctant to embrace this green giant once more, casting a shadow on the sector’s potential,” Fawzul said. “In a bid to salvage this vital part of our economy, the government’s intervention is now more crucial than ever. I request government intervention to prevent the industry’s extinction. It is the need of the hour for this industry to thrive further.”

While the concern is paramount, the bat manufacturers are keen to have raw materials at throwaway costs. “When we are ready to axe the mature willow, we seek buyers,” a willow grower, Abdul Rashid, said. “Technically, there are four main buyers for willow – the apple box makers, the ply-board makers, the pencil makers and the bat makers. After the apple growers moved to cardboard boxes, they no longer are in the race for willow. Ideally, the plywood and pencil makers can manage their raw material from poplars and even other trees, unlike the bat makers. To ensure they get the entire raw material, they must spend more. They want it to be on competitive pricing so they lose at the end as others offer better prices. If they need to protect their industry, they must give importance to raw materials. Why should a farmer wait for a decade and give them raw material at throw-away cost?”

This is a principle that is based on best practices and tradition. Even the government follows it. The Wular Conservation Project has axed tens of thousands of willow trees in north Kashmir. “We put everything related to willow into auction, and the highest bidder will get ownership of the materials,” Irfan Rasool, Conservator North Kashmir, said.

Mahmood Ahmad Shah, Director of Industries and Commerce, admits the raw material abundance in wetlands and insists there might not be a shortage at all. “Bat industry is flourishing, with an annual sale of 35-40 lakhs of bats,” Shah said. “We are on the path to deliver the introduction of advanced technologies to enhance production and quality.” Shah highlighted efforts aimed at obtaining Geographical Indication (GI) tagging for Kashmiri willow bats. “There is a concerted effort to promote the planting of female saplings to ensure the sustainability of willow resources used in bat manufacturing.”

“Regarding the raw material, we convened a meeting with industry representatives and forest department officials. We emphasized that there is no reliable census indicating a shortage of raw material for the bat industry,” Irfan Ali Shah, IFS, Conservator of Forests South Forest Circle, said. “Around 70 per cent of the raw material is sourced from Ganderbal and the Wullar area of Bandipora district, with only 30-35 per cent coming from South Kashmir. At present, no evidence or scientific study is suggesting a scarcity of raw materials.”

Authorities, however, are identifying ways and means to keep the raw material available. “I engaged in discussions with forest department officials and industry department representatives,” Irfan Ali informed. “We collectively concluded that the respective deputy commissioners should allocate state land to willow farmers, SKUAST Kashmir and other reputable research institutions so that they can provide improved genotypes of the raw material, which can be grown on the state land in a short time, offering them better returns.”

“The bat manufacturers are telling us that there is a shortage of willows by around 50 to 70 per cent,” added Irfan. “So, to dig out the reasons, we had this meeting, and, in that meeting, only this decision was taken.” He ruled out the possibility that the forest department could cultivate the willow for the industry in forest areas.

There is a serious debate within the policymakers over the alleged raw material issue. “There are players in the bat industry, who procure the willow clefts and sell it raw and smuggle it to bat makers in Punjab and UP,” one official said. “If they have a deficit at home, why do they sell it to other sports manufacturing facilities?” In 2017, nearly 25 lakh clefts were smuggled out despite a law preventing it and making it a punishable offence.

Surging Demand

Recent media reports in the wake of World Cup fever suggest a surge in bat-making. Kashmiri bats have made appearances in international cricketing events, a source of pride for Kashmir’s nearly 400 bat-makers. These hubs produce world-class willow bats sought by pros and amateurs alike.

As World Cup teams compete at the pinnacle, preference for these bats has soared, elevating their global profile. The thriving industry generates tens of thousands of direct and indirect livelihoods – from artisans to logistics and sales. It plays a vital economic role regionally.

This demand spike has ignited industry hopes. The upward trajectory sustains jobs and creates opportunities, underscoring its economic significance. In upcoming matches, 18 cricketers across Afghanistan, Sri Lanka and Bangladesh have remarkably chosen Kashmiri willow bats. Experts anticipate the World Cup will further boost preference, elevating the industry’s stature.