A breakthrough in carpet weaving technology in Kashmir is set to revive the ailing silk industry besides enabling Kashmir to trade in high end products that have been eluding the trade. Haroon Mirani reports.

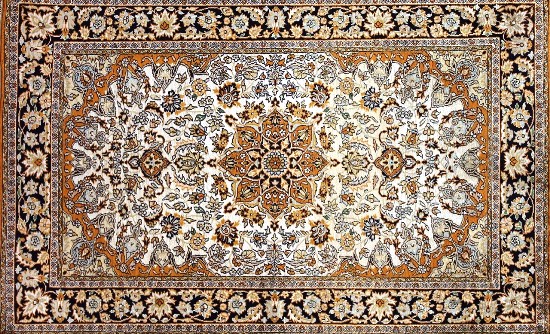

In a breakthrough for Kashmir’s carpet Industry, Srinagar based Indian Institute of Carpet Technology (IICT) has succeeded in weaving a reeled mulberry silk carpet, an Iranian forte so far.

The high end carpets command highest prices in market, and are produced mainly in Iran and a few other countries.

Kashmiri weavers could weave spun-silk carpets made from low quality silk fibres, usually the wastage in silk industry.

Despite highly skilled craftsmen, Kashmir had not been able to come up with a reeled mulberry silk carpet earlier.

Finally IICT succeeded in weaving such a carpet after a research of two and a half years.

“It took a lot of research to weave this carpet as we did not know anything about such type of weaving, use of fabric, dimensions and so on,” says Zubair Ahmad Mir, Director IICT.

The designers and weavers at the institute came up with a number of samples that were discarded for not being up to mark before succeeding in weaving the 5ft X 3ft carpet.

Mir lists the benefits of reeled mulberry carpets. “This kind of carpet fetches high price in international market and it will be an added attraction to Kashmir’s carpet industry,” says Mir.

In India, the carpet has the potential to become a monopolistic product from Kashmir. “A reeled mulberry silk carpet from Kashmir will surely attract buyers from around the world,” adds Mir.

On an average, the carpet can fetch 40 per cent more price than spun silk carpet.

Silk carpets have a long shelf life. “An ordinary spun-silk carpet can last 60 years while a reeled mulberry silk carpet has a life span of 200 years,” says Mir.

The idea of producing a reeled mulberry silk carpet at IICT came during an interaction with the Kashmir Chamber of Commerce and Industries (KCCI).

“If Iran can make such carpets why can’t Kashmiris make it?” the premier industrial body had asked the IICT.

The institute took the challenge and initiated a project that came up with the reeled mulberry silk carpet after two and a half years of effort. The process though doesn’t end here.

“Now the second step will be to propagate this craft to benefit people associated with this trade,” says Mir.

IICT is providing complete know how – specifications include dimensions and type of loom, quality of silk fibres and proportionate quantity of silk and cotton – of the technique of weaving Reeled Mulberry Silk carpets to craftsmen and traders who are willing to learn it.

Mulberry silk fibres are longer than spun silk. They also have a better lustre, shine and strength.

The introduction of mulberry silk carpets in Kashmir economy can not just benefit carpet industry, it can also revive the defunct silk industry of Kashmir.

“Unfortunately, about 80 per cent of silk cocoons produced in Kashmir are procured by outsiders and they earn millions from its value addition,” says Mir. “We don’t have the capacity to process silk here and most of our silk reeling industries have become defunct.”

Once silk is procured by carpet industry in huge volumes, most of high quality silk produced in Kashmir will be consumed indigenously.

Thousands of people would get employment as silk industries will have to be revived to process cocoons for meeting new demands.

The carpet produced has become a point of attraction with some of traders offering big amounts to purchase it. It has also been appreciated at exhibitions or places where it was displayed.

The quality is at par with those of Iranian carpets.

There is some inhibition among weavers about the high cost of raw material for this carpet. Mir says that the cost will come down ultimately.

“Reeled mulberry silk carpet has an edge over spun silk carpet as it uses 8 per cent less,” says Mir. “Secondly, when more silk industries will come up, the cost of raw material will correspondingly come down.”

Upbeat with their success, IICT has now embarked on a project to make a high end carpet with knottage in excess of 1600.

Although Kashmir’s carpet industry is facing a tough time, Mir says that recession doesn’t affect high quality products.

“If you offer a high quality product customers will always be available to take it, whatever the market situation,” says Mir.