Starting from one room of his house with financial help from friends, Abdul Rashid Dar set up Henna Agro Industries that sells 20 metric tonnes of pickles annually. Shazia Yousuf reports.

Year 1990: three friends, Abdul Rashid Dar, Bhushan Lal, and Jagdish Lal are sitting in the small house of Rashid – preparing themselves for a possible separation in the wake of turmoil. This may perhaps be the last time the childhood friends are sitting together, they think. Bhushan Lal breaks the silence, “And yes Rashid. Promise me you will start your own small business and leave this job. And you will not worry about money.”

Uncertain of whether his friends will have to leave Kashmir or will they be able to stay, Rashid tirelessly plans the things. By the end of month, the biggest room of his house changes into a small pickle making factory with the financial help of his Pandit friends who by now had decided to stay on.

The unit is named after the forthcoming Bollywood movie – Henna which they would not be able to watch together because the cinema halls have closed. Thus was born – Henna Agro Industries.

Till that year, Dar an unlettered 50 year old man worked in a Kashmir based manufacturing company- Hono jams as canning machine operator. He had been working in the company for 30 years, earning a meagre income to feed his family of seven and educate his four sons. “My friends who lived in Gogji Bagh were in trading business. They were aware of the difficulties I was undergoing due to financial problems. They gave me money and all the support in getting the business started. Pickle industry was their idea, given my 30 years of experience in the field,” Abdul Rashid says.

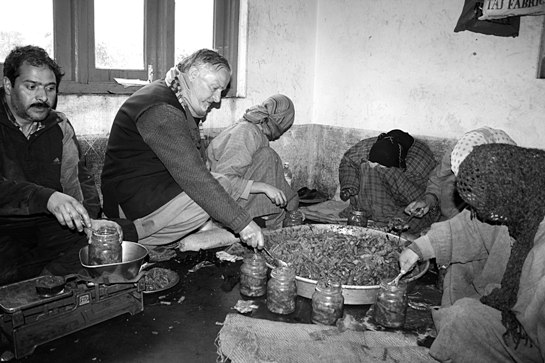

The unit was started in a single room of Rashid’s house at Kursu Rajbagh where he made some 40-50 bottles of pickles in the beginning, “It was sold in few days only. Then I started increasing the production and the business expanded. Gradually one whole story of my house and the compound would be required and I started employing people in my unit,” he says.

At present there are more than 20 employees working in his company which by now has been shifted to a residential colony in Padshahi Bagh Srinagar. It sells 20 metric tons of pickles annually with the annual turn over of 50 lakh rupees. And He has never taken help from any government or private organisation.

After some months of setting up of the unit Rashid was able to pay back the money he owed to his friends. Now the immediate requirement was to get FPO (fruit products order) license from Delhi. Again his friends knowing that he was unlettered accompanied him to Delhi, “They not only accompanied but spent all the required money and got FPO license for my unit.”

While his friends were busy with the formalities Rashid says he went to many food manufacturing units to see what he could do to make his business a success.

In 1992, Rashid got his unit provisionally registered under District Industry Center Budgam. By the end of third year, he was selling 10 metric tons of pickles annually and employed 10 workers mostly girls.

He says he did not go for any subsidy or loan, “I was an illiterate and thought it is better to work hard than to look for help or short cuts. The time that would go in roaming around government offices, I thought can be used in increasing the production. I wanted to work hard till my sons complete their studies so that they can take over later,” he says.

As years went by illiteracy was no more an obstacle. Rashid’s sons completed studies and joined hands in flourishing their father’s business. His eldest son Mushtaq Ahmad who earlier worked as a tailor also joined in. Another son Muzaffar Ahmad Dar who also works as sales representative in Nestle India manages the marketing part, “We don’t allow our father to work anymore. We have divided the work and I do all the legal formalities that are required from time to time,” says Rashid’s another son, Javed, a post graduate in biotechnology.

In 2004, they purchased land in Padshahi Bagh locality and established a full fledged factory there. Untill then all work was done at their residential house.

The family is planning to shift the company to Industrial Estate Rangreth and expand the production by making the company semi-automatic. All the work, be it grinding of spices or cutting of vegetables, is done manually. Rashid says he doesn’t want to go for full automation.

“Many girls who have been working here from many years will lose their jobs. Most of them have some social or economic problem in their homes and come from far off places. And more importantly I will lose that sense of satisfaction that comes from providing employment to any person,” says Rashid.

Government modalities or even incentives have discouraged him. Rashid says in the beginning he went to the authorities a couple of times but gave up after seeing their functioning, “I was a labourer and knew what it takes to earn money. Huge bribes sought by officials discouraged me. For illiterate people like me the formalities are troublesome.”

Javed adds that even though the industry is exempt from tax the company pays tax both at the purchase of raw material and sale because of the hassles in modalities.

“And when it comes to subsidy on raw material, electricity and other things, we don’t make any use of it,” informs Javed.

He adds the company procures raw material from locals, “It is our father’s wish that our own people like vegetable sellers should get benefited from our work,” says Javed.

The company is registered under Home scale category II license for manufacture of pickles and jams, and sells 20 metric tons per annum or 20,000 kgs of pickles annually. The product is sold in three different packages – polypack, glass pack and jerrycan pack. The company also processes honey. Besides, the company is ready to start canning of fruits and vegetables.

With automation the company is expecting increased turn over. “We do everything manually that consumes lot of time. Though the product that comes after manual processing is of better quality, we are planning to make use of some machines without compromising on the product quality,” says Javed.

At present, Javed says, they caters to the 20 per cent of Srinagar market. “Though it is later sent to Ladakh and outside district, we sell out products in Srinagar only. Eighty percent of Srinagar and district markets is our target and we want our product to be available in Delhi and other states of India,” Javed says.

Twenty years have passed. Abdul Rashid has turned 70. His dream of handing over the company to his educated children has been realised.

Ask him to have his say, “Sometimes I sit and think. Where I was and where have I reached. A worker in a small company owns a company of his own, it feels nice. Sometimes in peak seasons like Ramadhan and marriage season our stock exhausts much before the expected time. Earlier I would get vegetables on shoulder now they are supplied in vehicles. I feel proud.”

“I would work day and night. Today I am only asked to do mixing part of it because my sons don’t want me to pass on its preparation to anybody yet,” he adds.

And those days are still special when Bhushan Lal and Jagdish Lal visit the ‘dream’ company.